Dear Friends,

How do you think about induction heater for PWHT.

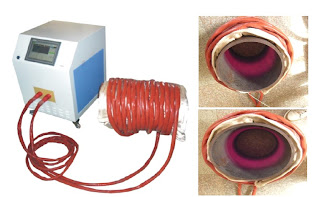

We supply induction heater for PWHT. Pls check the pic.

.jpg)

1. Around the insulation blanket on the pipe.

2. Around the induction coil on the insulation blanket. (10 ~ 15 turns will be ok)

3. Connect the induction coil on the induction heater.

4. Connect the K type thermocouple on the induction heater. Setting the heating process. The machine will ok.

5. Start the induction heater then It will work well.

It has many advantage compare with resistence heater:

- Quickly heating speed. It can reach 650 degree C within 30 minutes. It will save many times compare with resistence heater.

- Electrical Power Saving: It can save more than 50% electrical power compare with resistence heater.

- Stable for long time using: The equipment and induction coil are more stable compare with resistence heater

- Easy to operate and move and so on.

- The control system is touch PLC screen.

在 2009年7月4日星期六UTC+8下午10时47分39秒,sonu写道:

Hello to all of you.--

Dear friends I have one query which I like to ask you

As per table 331.1.1 of ASME B31.3,it is mentioned here the

requirement of PWHT as per thickness and tensile strength for

mentioned materials.But how can I get information according to service

vise? This requirement is depend on project specification but i want

to know that, on which basis they calculate this requirement? Which

factors will consider during calculation? and how this factors affect

during service?

Regards

SADIQUE

To post to this group, send email to materials-welding@googlegroups.com

To unsubscribe from this group, send email to materials-welding+unsubscribe@googlegroups.com

For more options, visit this group's bolg at http://materials-welding.blogspot.com/

http://www.linkedin.com/groups/MaterialsWelding-122787?home=&gid=122787&trk=anet_ug_hm

The views expressed/exchnaged in this group are members personel views and meant for educational purposes only, Users must take their own decisions w.r.t. applicable code/standard/contract documents.

Comments