How we can prove it , There is any documents that's says about with painting can perform RT for Weld Joint, When we propose to client we have to submit some supporting documents

If you have any supporting documents , Please share with me

On Friday, October 21, 2022 at 8:55:40 AM UTC+3 Babur Khan wrote:

Greetings,

Yes you can do RT with Paint.

Coating or painting can hide only visual defects.

Buried defects can be detected with RT.

Muhammad Babur Khan

Gents,

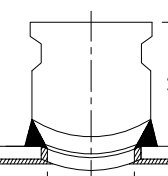

i have query , We can do RT for weld Joint with painting , Its allowed , In our site they did RT with painted joint with out client approval

They will be problem that may hide weld defect , painting DFT 300 to 400 micron

If allowed do RT with Painting , Please share some supporting documents

Thanks for your support

Best regards

Sankar.k

--

https://materials-welding.blogspot.com/ https://www.linkedin.com/groups/122787 ---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to

materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit

https://groups.google.com/d/msgid/materials-welding/ce432779-6877-4dce-8ce6-843e0802d7d2n%40googlegroups.com.