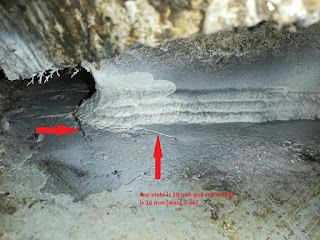

--Dear AllWe have encountered a critical issue with the joints from the beam to the main plate on the Spud Can top plate of our jack-up rig. Upon welding and subsequently lowering the spud can into the water using the jacking system, cracks have emerged in three of the joints that were welded previously ( according to photos cracks happen on the plate) This is a concerning development, and we must address it promptly to ensure the integrity and safety of our spud can.Considering that in the area where we are, the depth of water is low and there is not much pressure on the spud can, the reason why this happens is not clear to us, and if anyone can advise on this matter, I would be very grateful.Main top plate thickness is 19 mm and crack depth is 16 mm.RegardsBabak

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1896576593.3616147.1711818946138%40mail.yahoo.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CA%2BQ29Oh9VrhwX9PQU0OO1Vrf1gN7Et70VMVCY5HRVAQfW_Tdaw%40mail.gmail.com.