You can discuss with your client of weld metal chemistry after depositing to required GTAW thickness to verify 'Mo" content.

But the best way to go with API RP-582 recemendation and convince your client that weld joint need high temperature oxidation resistant weld metal rather pitting resistant which alloying with 'Mo" would provide . Dissimilar weld joints are mostly accepted based on application requirement.But again client's discretion. ER309LMo should have been better choice even Alloy 625 to begin with.

Regards

Amitabh

On Wednesday, May 27, 2020, 11:22:16 AM EDT, Prasad <prasadloke27@gmail.com> wrote:

Dear Expert need your opinion.

I have WPS/PQR of dissimilar metal GTAW (F11 to SS316L) with Inconel Filler for high temperature application. Inconel filler selected according to API 582 guidelines..but our end user is not accepting Inconel filler because it doesn't have Moly content which is present in base metal.

Any document or write to prove correctness of Inconel filler?

On Tuesday, September 20, 2016 at 11:12:09 AM UTC+5:30, vijay Katkar wrote:

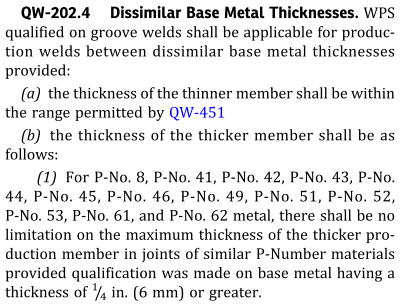

Dear Expert,Need your guidance,I have PQR with P1 to P43 with 10 mm thickness,Can i use this PQR for Joint with 10 mm (P1) & 45 mm (P43) under following clause?Clause no QW 202.4.Thank youVijay Katkar

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1db890c8-5cc2-4bae-b53a-ab54a0ee014e%40googlegroups.com.

Comments