Hi Prem

I have a similar situation and I hope replies to the mail will also be of use to me.

Code AWS d1.1

Existing wps eh36 to eh36 material

Qualified range groove thickness max 50mm without PWHT

The pqr coupon was eh36 to eh36 material

Current situation details

4140 bar 200 dia welded to 100 mm eh36 plate fillet weld throat is 16 mm.

Query

Can I use the above wps by using appropriate electrode which is within the AWS 5.20.

Your advise will be appreciated

Thanks

Rudolf

Sent from my iPhone

--HiWe have successfully welded 42CrMo4 in past with E8018-B2, Preheat min. 150-200 degree celcius followed by PWHT.RegardsPrem Nautiyal

From: muhammad bilal <muhammadbilal6@gmail.com>

To: materials-welding@googlegroups.com

Sent: Tuesday, July 30, 2013 1:32 PM

Subject: [MW:18297] Re: 42CrMo4 ( SAE 4140 ) Welding

Dear All!We have a screw 7inch diameter made of AISI 4140, its edges are wear our we have to build up, what will be best welding consumable and procedure.Is 300C pre-heat necessary.........also 590-600C is post heat of PWHT, what is holding time?RegardsM Bilal--

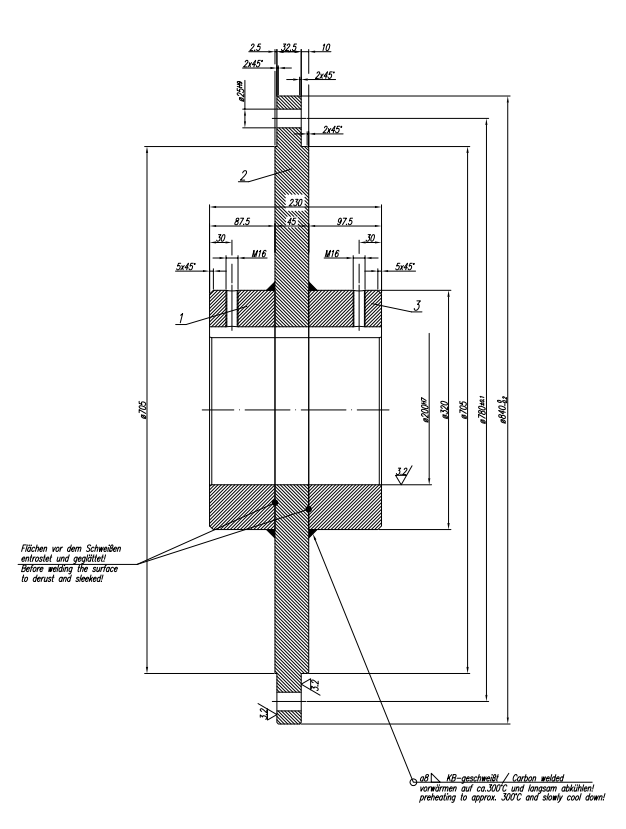

On Thursday, 11 August 2011 10:26:30 UTC+5, Sinan ARSLAN wrote:Hi,As you seen on drawing we will do fillet weld at this ring.The material grade 42CrMo4 ( SAE 4140 ).I searched on internet it must be apply preheating which degree nearly 316ᵒ C before welding and after welding it must be apply heat thearetment ( 590 ᵒC-600 ᵒC ) and than cool down at room temperature.Now i am looking an electrode for this material.At enclosed i added speciality for this material.Could you advice me an electrode for this material?Which electrode?

--

Saygılarımla.

Best Regards.

Sinan ARSLANMechanical Eng.Welding Eng.

To post to this group, send email to materials-welding@googlegroups.com

To unsubscribe from this group, send email to materials-welding+unsubscribe@googlegroups.com

For more options, visit this group's bolg at http://materials-welding.blogspot.com/

http://www.linkedin.com/groups/MaterialsWelding-122787?home=&gid=122787&trk=anet_ug_hm

The views expressed/exchnaged in this group are members personel views and meant for educational purposes only, Users must take their own decisions w.r.t. applicable code/standard/contract documents.

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

For more options, visit https://groups.google.com/groups/opt_out.

To post to this group, send email to materials-welding@googlegroups.com

To unsubscribe from this group, send email to materials-welding+unsubscribe@googlegroups.com

For more options, visit this group's bolg at http://materials-welding.blogspot.com/

http://www.linkedin.com/groups/MaterialsWelding-122787?home=&gid=122787&trk=anet_ug_hm

The views expressed/exchnaged in this group are members personel views and meant for educational purposes only, Users must take their own decisions w.r.t. applicable code/standard/contract documents.

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

For more options, visit https://groups.google.com/groups/opt_out.

Comments