Dear Bala Guru

Thanks for the prompt reply and clarification for the same.

It could be possible for you to mention names of filler material as per the PNos you mentioned or Section II C is enough for understanding.

Thanks

Razz Khan

From: materials-welding@googlegroups.com [mailto:materials-welding@googlegroups.com] On Behalf Of Bala Guru Nathan

Sent: Thursday, August 24, 2017 3:44 PM

To: Materials & Welding

Subject: [MW:26755] Re: Base metal and Weld metal combination

Dear Mr Razz Khan,

To reduce the number of welding qualifications with respect to the vast variety of base materials, ASME has categorized the materials into P No (Parent material No) based on their characteristics like chemical composition, mechanical properties and WELDABILITY.

For Example (based upon chemical composition & Mechanical Properties),

P No 1 - Carbon Manganese Steels

P No 3 - 1/2 Mo or 1/2 Chromium Steels

P No 4 - 1.25 Chromium - 0.5 Molybdenum Steels

(Similarly based upon weldability problems,

P No 4 - Steels susceptible to Hydrogen Induced Cracking/Cold Cracking

P No 8 - Steels susceptible to Hot Cracking

So Materials listed under particular P No will have similar weldability problems and prime focus should be given to mitigate the same.

Coming back to your Case 1 : It does not qualify P No 1 to P No 1 because the electrode you would have used to weld for your WPS is E9018-B1 where as the recommended electrode for C-Mn steels are E7018, So if you use E9018-B1 for C-Mn Steels welding, your weld metal will have very high T.S (Approx 140 Mpa) than base metal ( Ductility would be reduced; Could fail bend test ) which in some cases are not allowed.

The same above explanation applies for your Case 2 also, where recommended electrode for P No 4 to P No 4 is E9018-B9.

To add further, Welding of P No 3 to P No 1 is allowed because one of the acceptance criteria for dissimilar welding is that the tensile strength of the weld should be between either of T.S of base materials. So, E9018-B1 could be used that causes gradual variation in T.S along the weldment occurs.

Hope this explains your queries.

Regards,

Bala Guru Nathan,

QA/QC Engineer, L&T Construction.

On Thursday, August 24, 2017 at 4:36:16 PM UTC+5:30, asif.raza wrote:

Dear all experts.

Pl need feedback and further in depth understanding on the following points:

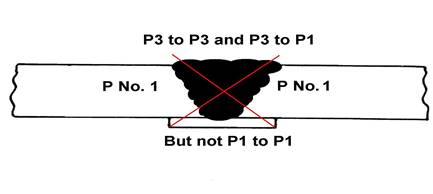

Case1:

one metal from P No. 3 to any

metal from P No. 3 does not qualify P No. 1 to P No. 1

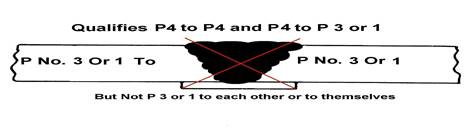

Case 2:

It qualifies one metal from P No. 4 to any

metal from P No. 4, 3 or 1. but does not qualify P No. 3 to P No. 3 or P No. 1 to P No.1

I would much appreciate if someone give more details regarding, grouping for base metals with weld metals, for similar and dissimilar metals.

Thanks

Razz Khan

Welding Inspector

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

Visit this group at https://groups.google.com/group/materials-welding.

For more options, visit https://groups.google.com/d/optout.

Comments