Re: [MW:33334] Re: 33319] CS material, E70S2- Welder qualified , can he weld SS 316 material & Duplex, Super duplex material with E70s2 qualification ? or he should be qualified by separate SS 316 & Duplex ,SDSS material ?

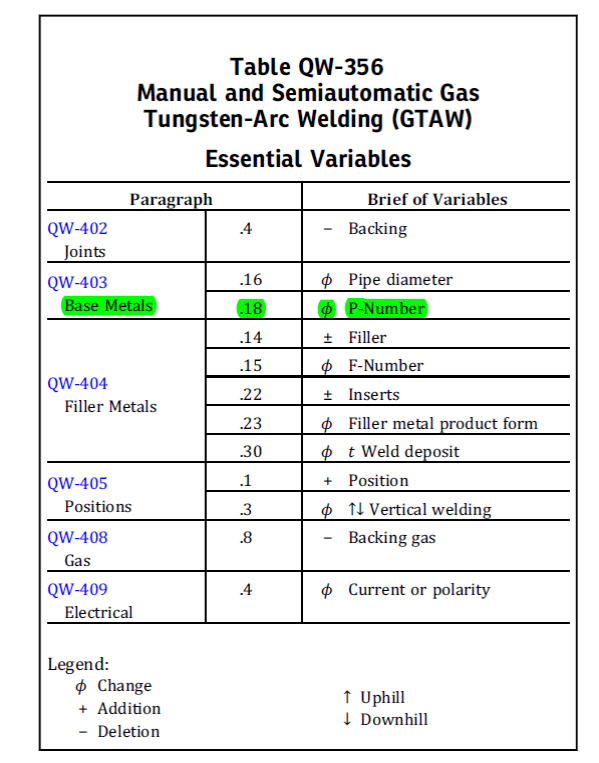

Some contractors use the essential variable tables (QW-352 thru 357) to minimize their costs. For instance, they might test the welder for stainless steel material by using carbon steel material.

Consider the actual project material is stainless steel and you do not want to waste stainless steel material for testing.

You ask the welder to weld in carbon steel material but with stainless steel filler metal.

Ø Based on the essential variable table P number 1 (Carbon Steel) qualifies P 8 (Stainless Steel), and the

Ø F number is the same.

Ø So you qualify your welder for stainless steel material by using carbon steel material but stainless steel filler metal.

Ø Adding back gas(purge gas) for SS welding -NO ESSENTIAL VARIABLE

Dear Madheswaran ,

As general understanding of code ,If the Essential variables of CS qualified by the welder are not changes, then the welder is allowed to weld SS material as permitted by the ASME SEC IX , QW-423, There is only one major change in SS welding is back purging(backing). A welder qualified without backing, can weld with backing as per ASME sec IX this is only limited to GTAW process/the process where essential variables are not changed

So a welder qualified in CS without purging can weld SS with purging. But one has to consider other variables like are this welder cable to do welding in case of purging, is he aware of welding variable, other welding requirements to be followed for material mainly inter pass, travel speeds.

Considering the base material chemistry , metallurgy and criticality of the job one shall not allow CS qualified welder for SASS, DSS, SDSS welding even though code permits.

thanks& regards,Hi,

The welder is not qualified to weld SS 316 or DSS or SDSS. Though the F No for consumables remain to be the same , the P No gets changed. Hence welder will require new qualification.

Thanks.

Pradip Goswami.P.Eng, IWE.

Independent Welding & Metallurgical Engineering Specialist

Saudi Aramco Approved Designated Project Welding Engineer (DPWR)

Qatar Petroleum Approved, SME-Materials & Corrosion Engineering.

Linkedin: https://www.linkedin.com/in/pradip-goswami-2999855/

Email:pgos...@rogers.com,pradip....@gmail.com

Cell/Whasapp:1-905-9793232

From: material...@googlegroups.com <material...@googlegroups.com> On Behalf Of Madheswaran s

Sent: July 29, 2022 2:12 AM

To: Materials & Welding <material...@googlegroups.com>

Subject: [MW:33319] CS material, E70S2- Welder qualified , can he weld SS 316 material & Duplex, Super duplex material with E70s2 qualification ? or he should be qualified by separate SS 316 & Duplex ,SDSS material ?

Dear Experts,

CS material, E70S2- Welder qualified , can he weld SS 316 material & Duplex, Super duplex material with already he has E70s2 qualification ? or he should be qualified by separately for SS 316 & Duplex ,SDSS material ?

Thanks,

Madheswarn.S

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/2d44c76c-a78f-402e-80a7-0616f1c9ca0an%40googlegroups.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit

Comments