Dear Ganesh,

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/f58c81dd-ac74-499a-a1a4-a1d09fb34a56n%40googlegroups.com.

your undestanding was correct , go ahead.

kindly ignore mail from Mr. V.Kingsly Geo. BCZ it is applicable for perfromace qualification.

Thanks

Srinivas Rao

On Monday, July 25, 2022 at 12:14:43 PM UTC+4 kingsly...@gmail.com wrote:

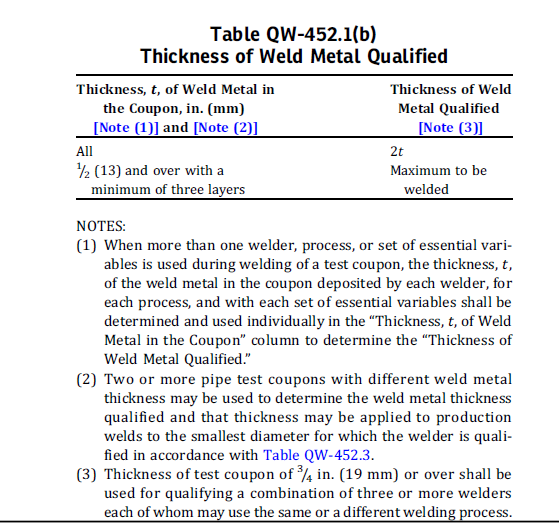

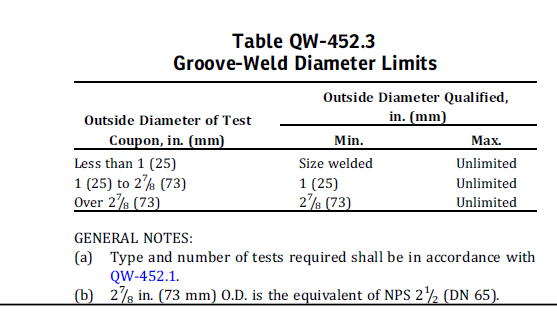

Dear Ganesh,Job PQR thickness - 25.4mmProcess - GTAW (4mm)+ SMAW(21.4)as per ASME sec IX, Qualifications range for GTAW 4mm --- min - 5mm, max- that is <19mm, 2t =8mm ---------------- GTAW - MAX 2t - 8 MMQualifications range for SMAW 21.4mm -- min-5mm, max- that is >19mm, 2T=2(25.4)=50.8mm ---------------- SMAW - Unlimited Thickness if PQR has been done with 3 layers of welding.So..The total thickness welded is 25.4(4+21.4)mmTotal thickness qualified is -=8+50.8=58.8mm --------------- GTAW - 8 MM MAX & SMAW Unlimited thicknessRegards,V.Kingsly Geo.On Mon, 30 May 2022 at 07:12, Ganesh Muthurajan <qcen...@gmail.com> wrote:Gent'sCan any one explain with example of thickness qualifications - procedure.Especially for combination of process with 19mm to 38mm thickness job welded.Explain me each and every step.Here I explain what I am understand that code. Weather it's wrong please explain.Example.Job PQR thickness - 25.4mmProcess - GTAW (4mm)+ SMAW(21.4)as per ASME sec IX, Qualifications range for GTAW 4mm --- min - 5mm, max- that is <19mm, 2t =8mmQualifications range for SMAW 21.4mm -- min-5mm, max- that is >19mm, 2T=2(25.4)=50.8mmSo..The total thickness welded is 25.4(4+21.4)mmTotal thickness qualified is -=8+50.8=58.8mmIs that correct or not.If it wrong kindly give me a brief lesson to me.Thank youGaneshQC Welding--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAM0EmFJmvaHw6Nv%3DO%3Dm3-0N%2BGS-j0uED9QkRP%3DaXzE3%3DphOGEw%40mail.gmail.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/f58c81dd-ac74-499a-a1a4-a1d09fb34a56n%40googlegroups.com.

Comments