Hi,

I think there're some mix-ups in the specifications and interpretations. SSPC SP6 or other specifications are applicable for surface preparation by blasting for application of paints.

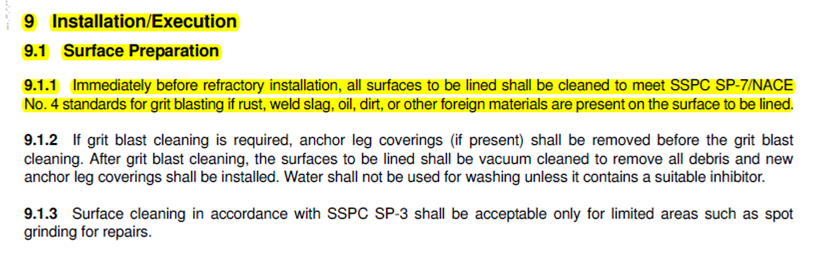

For the refractories the criteria is a bit different. Following is the extract from API -936, for surface preparation before applications of refractory.

You may read the standard, discuss and settle the issue with the client based on the API-936 guidelines.

Thanks.

P.Goswami.P.Eng, IWE.

Independent & Consulting Welding & Metallurgical Specialist

Linkedin: https://www.linkedin.com/in/pradip-goswami-2999855/

Email:pgos...@rogers.com,pradip....@gmail.com

Cell/Whasapp:1-905-9793232

From: RKD <raymondkenn...@gmail.com>

Sent: November 26, 2020 10:15 AM

To: Materials & Welding <material...@googlegroups.com>

Subject: SSPC SP 6 - 63

Hello everyone.

I encountered a requirement from a Licensor specification that internal surface should be prepared as per SSPC SP 6 - 63 prior to refractory application.

I know SSPC SP 6 means commercial blast but I have never encountered or saw a surface preparation requirement "SP 6 - 63".

Does anyone know what this means?

Thank you in advance.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/dd6f9852-14ad-4624-916f-9c4acf80a29dn%40googlegroups.com.

Comments