On Mon, 1 Jun 2020 at 22:24, Zeghanu Gigi <xxxxxxxxxxx@xxxxxxxxx> wrote:

The answer to your problem is delicate/complex.Just I would like to remind you that the main problem ,in my opinion ,is to solve Type IV Cracking for DMW.There are lot of documents related this subject on internet ,especially from Bhadeshia Professor. My advice is to try to study and understand the phenomena ,then you can try to get decision regarding filler metal suitable for this kind of welded joints.Even you have no time try to organize your program accordingly.Keep in mind that the codes and standards are guide,never replace engineering experience.After study possible to decide to don't weld direct ferritic creep resistant steel (F11) to Austenitic Stainless Steel 316L ,especially at elevated temperature.Buttering solution.....My opinion is that no Mo is the key of this problem.I will send you tomorrow some documents related these very old but still actual problem.RegardsGigi

On Tuesday, September 20, 2016 at 11:12:09 AM UTC+5:30, vijay Katkar wrote:

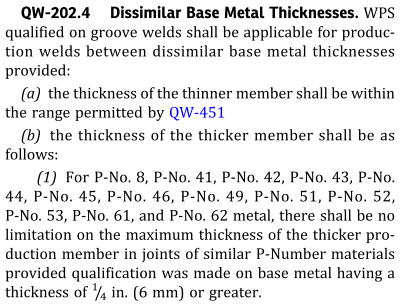

Dear Expert,Need your guidance,I have PQR with P1 to P43 with 10 mm thickness,Can i use this PQR for Joint with 10 mm (P1) & 45 mm (P43) under following clause?Clause no QW 202.4.Thank youVijay Katkar

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/2fa236c3-d191-476d-902f-3bb35f2156b6%40googlegroups.com.

No comments:

Post a Comment