Thanks & Regards

J.Gerald Jayakumar

--Gents,Below other experts opinion.....The operating experience of direct (without buttering layer) ferritic/austenitic junction revealed poor performance in power plants. The use of direct joint between ferritic steel and austenitic stainless steel has led to several problems in service like thermally induced cyclic stresses resulting from the difference in coefficients of thermal expansion between the ferritic and austenitic steels (difference in coefficient of thermal expansion of these two materials is ~30–40%) Earlier, ER 308L and 309L were used to join these materials but resulted in premature failures due to carbon migration (formation of the soft zone between Cr-Mo and ER308/309) and sigma phase formation. Nickel based consumables (Inconel 82 and Inconel 182) possible to offers the best compromise between these materials because it significantly retards carbon migration and gives improved thermal stability.On Tuesday, 2 June 2020, 09:24:35 EEST, Kannayeram Gnanapandithan <kgpandithan@gmail.com> wrote:As Mr. Wilfred said, when weld metal of NiCrMo3 is exposed to high temperature with longer period, second hardening is taking place. Ref EPRI on Cr-Mo steel--On Mon, 1 Jun 2020 9:02 pm Raghuram Bathula, <raghurambathula@gmail.com> wrote:--can you please give this book referenceThanksOn Mon, 1 Jun 2020 at 20:22, 'wilfred kojo' via Materials & Welding <materials-welding@googlegroups.com> wrote:Again, welding with ENiCrMo-3 or ERNiCrMo-3 is also not a good choice due high tendency of forming brittle phases – see attached.

If the client insist using filler metal with molybdenum, then your best choice is INCO A (ENiCrFe -2 ) with Mo content of between 0.5 – 2.5 – see attached also.

Sent from Mail for Windows 10

From: 'wilfred kojo' via Materials & Welding

Sent: Monday, 1 June 2020 3:32 am

To: Materials & Welding

Subject: Re: [MW:30949] Re: Welding of Dissimilar Thickness & Dissimilar P number

For high temperature service, 309L is not the best filler. The different in CTE (coefficient of thermal expansion) between low alloy steel and stainless steel is high. During thermal cycling, the difference in CTE create shear stress at the weld interface between stainless steel weld metal and the low alloy steel. Again, during welding there is diffusion of carbon from the heat affected zone of low alloy steel to the stainless steel weld metal due to high affinity of carbon to chromium (carbon diffuses from region of low chromium content to region of high chromium content) creating region in the HAZ with low carbon and low creep strength. The shear stress and the region of low creep strength lead to early failure in service. This is the reason while nickel base filler metal often preferred and recommended.

On Thursday, 28 May 2020, 04:36:16 GMT+1, 'Amitabh Bhattacharya' via Materials & Welding <materials-welding@googlegroups.com> wrote:

You can discuss with your client of weld metal chemistry after depositing to required GTAW thickness to verify 'Mo" content.

But the best way to go with API RP-582 recemendation and convince your client that weld joint need high temperature oxidation resistant weld metal rather pitting resistant which alloying with 'Mo" would provide . Dissimilar weld joints are mostly accepted based on application requirement.But again client's discretion. ER309LMo should have been better choice even Alloy 625 to begin with.

Regards

Amitabh

On Wednesday, May 27, 2020, 11:22:16 AM EDT, Prasad <prasadloke27@gmail.com> wrote:

Dear Expert need your opinion.

I have WPS/PQR of dissimilar metal GTAW (F11 to SS316L) with Inconel Filler for high temperature application. Inconel filler selected according to API 582 guidelines..but our end user is not accepting Inconel filler because it doesn't have Moly content which is present in base metal.

Any document or write to prove correctness of Inconel filler?

On Tuesday, September 20, 2016 at 11:12:09 AM UTC+5:30, vijay Katkar wrote:Dear Expert,

Need your guidance,

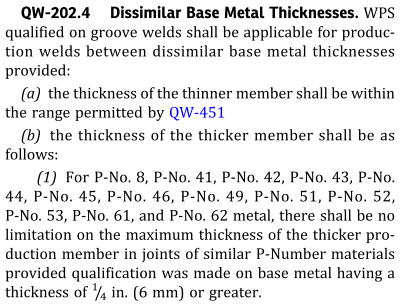

I have PQR with P1 to P43 with 10 mm thickness,

Can i use this PQR for Joint with 10 mm (P1) & 45 mm (P43) under following clause?

Clause no QW 202.4.

Thank you

Vijay Katkar

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CADxVubm4J4xwEONMaktNQYRwrxDKXZ_Y07_MneTo20mmMPn6oQ%40mail.gmail.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4eMKuXRDv3%3D69qGDfyWvEJ0qDe817Vqkkb8MLaxrWAcdHg%40mail.gmail.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/958539051.226968.1591082975865%40mail.yahoo.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAAS23SLqSeM-zbpMzzjLLcKxU5q-CH6YF-tCA-8N-TER7hqvNw%40mail.gmail.com.

Comments