in my opinion, QW 407.4 does not apply to weld metal thickness.

On Saturday, 3 June 2017 09:25:35 UTC+4, vijay Katkar wrote:

Dear Sir,

Need your help on following issue,

I have PQR with 88 mm thickness ( SMAW – 32 mm & SAW -56 mm)and it has normalizing + stress reliving heat treatment. Generally it is used for dish end long seam (where fiber elongation is more than 5%).

As per QW 407.4 Base material thickness T will be qualified 1.1 times of test coupon thickness, in my case it will be 96 mm maximum and deposition thickness will be as per QW 451 table but shall not be more than base metal thickness. As per my assumption SMAW- up to 96mm & SAW- up to 96mm will qualify.

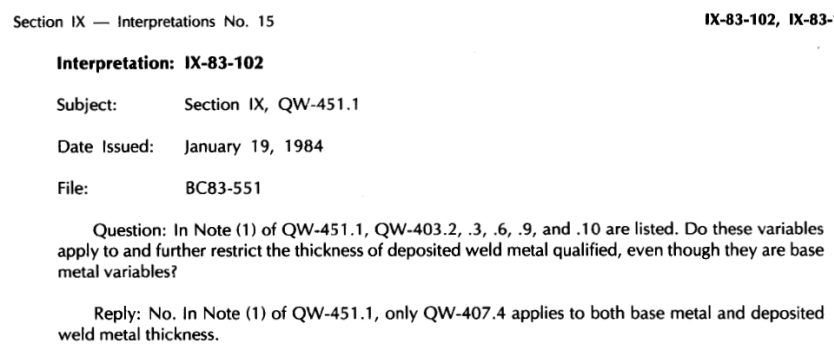

As per interpretation IX 83-102. Both thickness will qualify 1.1 times. It means that SMAW will qualify up to 35 mm & SAW - 61 mm. Is this interpretation valid as per latest code requirement?

I have attached interpretation copy for your reference.

Vijay Katkar

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

Visit this group at https://groups.google.com/group/materials-welding.

For more options, visit https://groups.google.com/d/optout.

Comments