Rather than giving a Fish to Eat, it is better to teach them fishing.

Just a proverb.

If it is for Production test coupon.

1. Charpy specimen size is 10x10x55 mm (width is 10mm).

2. I set of charpy specimen contains 3 number of specimen.

3. so calculate the total specimen and multiply with width.

4. Check with the charpy testing LAB the cutting allowance for specimen.

5. Put a rough check and calculate.

Please also check with the Lab as Lab people are very knowledgeable.

Thanks & Regards

J.Gerald Jayakumar

On Tuesday, 4 October, 2022 at 03:07:07 pm GMT+4, williams p wilson <williamswilsonp@gmail.com> wrote:

Dear Gerald Sir,

Greetings!!

Please advise the dimensions of the test plate.

300 mm (W) x 500 mm (L) is enough.

In our case one test plate is required for each welding procedure used for Cat. A & B Joints.

80 mm thick dish heads are manufactured with a single joint - PTC is required for these joints.

Thank You & Regards

Williams P Wilson

+968-94600828

QA/QC Engineer

Please consider the environment before printing this message

On Tue, Oct 4, 2022 at 1:14 PM Sezgin Ckllı <euniversty@gmail.com> wrote:

Thank you Mr. Gerald.Believe me, you've been very helpful.Thanks & Regards

Sezgin ÇAKALLI

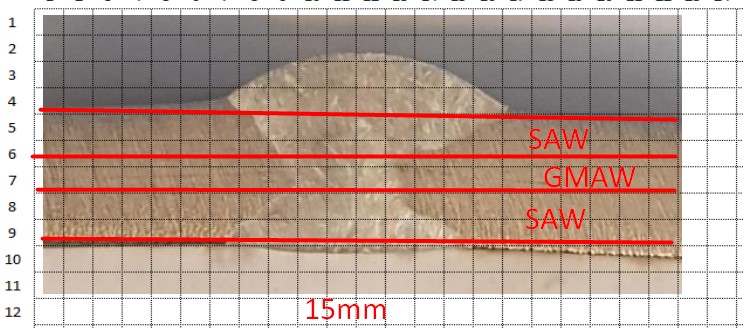

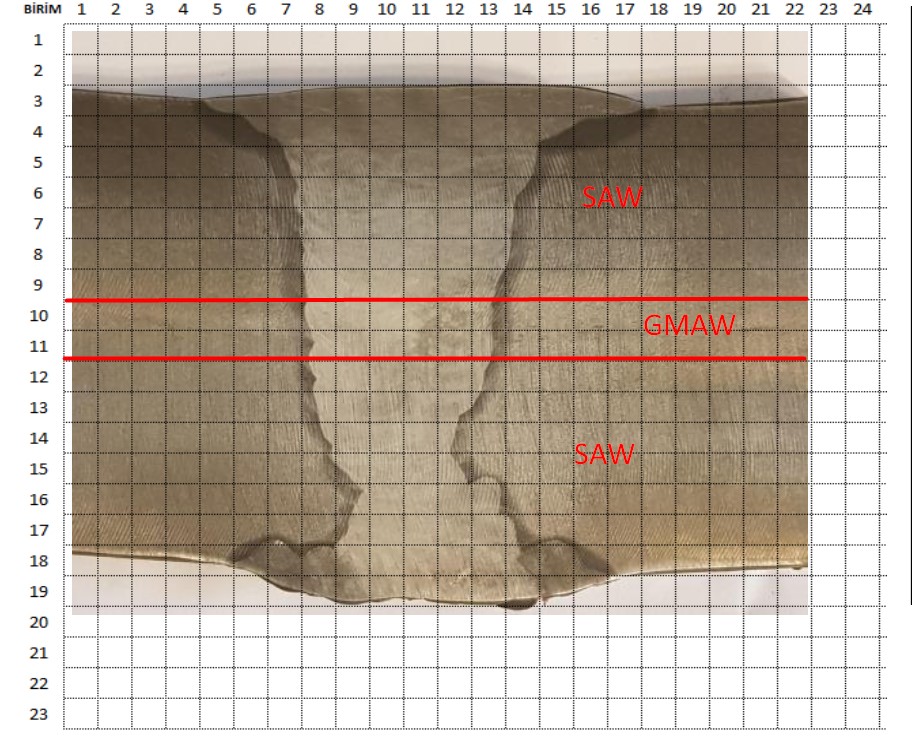

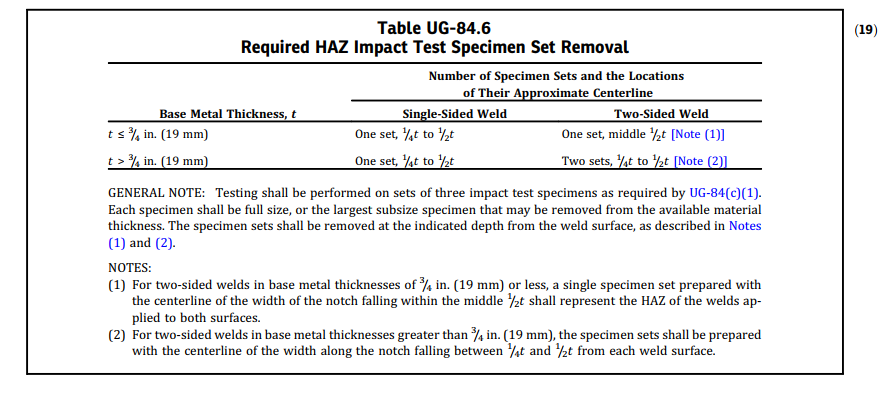

--4 Ekim 2022 Salı tarihinde saat 06:20:02 UTC+3 itibarıyla gerry_tup şunları yazdı:Figure (1)Weld (Thickness 15mm)1 set with notch in the weld 1.5mm from the top surface (SAW Process)If GMAW weld metal greater than 2.5mm, 1 set in GMAW weld subsizeHAZ1 set from 1/4t to 1/2t in SAW HAZIf GMAW weld metal greater than 2.5mm, 1 set in GMAW HAZ subsizeFigure(2) 50mmWeld1 set 1.5mm from the surface with the notch in the SAW weld1 set below the GMAW weld in the SAW weld near to centerline and notch in SAW weldIf GMAW weld metal greater than 2.5mm, 1 set in GMAW weld subsizeHAZ2 sets in HAZ as per table 84.6If GMAW weld metal greater than 2.5mm, 1 set in GMAW HAZ subsizeFigure (3) 35mmWeld1 set with notch in the weld 1.5mm from the top surface (SAW Process)1 set with notch in the weld 1.5mm from the root surface (GTAW Process)subsizeHAZ2 sets in HAZ as per table 84.6If GTAW weld metal greater than 2.5mm, 1 set in GTAW HAZ subsizeThanks & Regards

J.Gerald Jayakumar

That's why we subjected it to the impact test.

What I want to learn is how many samples should be taken from where in the sourced material I want to specify below?I will be glad, if you inform me.

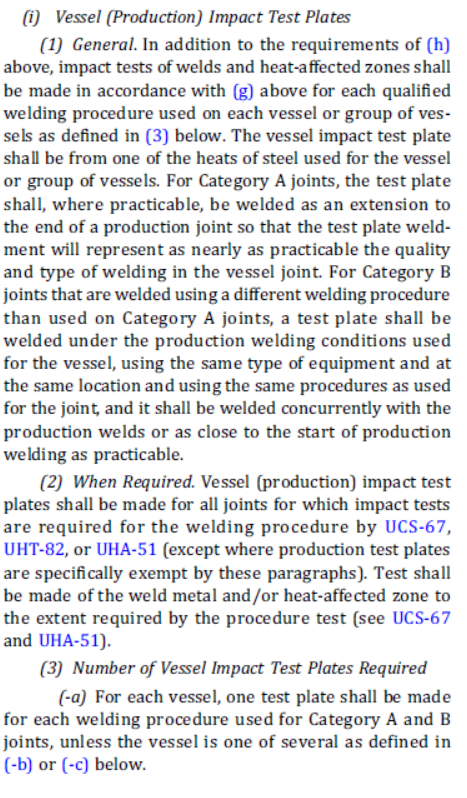

Yours truly--3 Ekim 2022 Pazartesi tarihinde saat 12:43:30 UTC+3 itibarıyla gerry_tup şunları yazdı:When Impact testing is a design requirement as per ASME Sec.VIII Div.I, production Impact testing is required. Only Impact test is the requirement as per ASME Sec.VIII Div.I unless other tests are required by your Client Requirement.For production Impact test follow below section.For any specific requirement as per below table, please describe in detail what clarification you require.Thanks & Regards

J.Gerald Jayakumar

Thank you Mr. J. GrealdBut as far as I have learned, please pay attention to the following paragraph and confirm its accuracy.**

RegardsSezgin ÇAKALLI--3 Ekim 2022 Pazartesi tarihinde saat 07:43:02 UTC+3 itibarıyla gerry_tup şunları yazdı:UG-84Thanks & Regards

J.Gerald Jayakumar

We design a pressure vessel according to ASME VIII Div.1 and our customer request shows "Production test plates according to Code requirements". Can you tell us the section showing where we can take samples from materials that vary according to their thickness. Or I need someone to contact me about the issue.

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/3ff85526-0de0-44a3-b2f3-6ec89fe81124n%40googlegroups.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/6278e0fc-2cf7-4528-a601-534d5a421c02n%40googlegroups.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/e213243d-1b70-4c51-99ae-f9bc26d494fen%40googlegroups.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/e38ad76c-ec2e-41fb-96a0-073cdcb02d10n%40googlegroups.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAHBxnQ7B%3DJRnAO5%2BG8kCSn6sU6TKuYKoqeTgBmEnfkR62Zqzow%40mail.gmail.com.

Comments