Thanks

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/da57bdef-0903-4496-823b-dbed31173e06n%40googlegroups.com.

Pl help to inform the name of the book /literature from where the below snap is taken

Thanks and regards

Vishwas

On Tuesday, October 11, 2022 at 11:19:23 AM UTC+5:30 gerry_tup wrote:

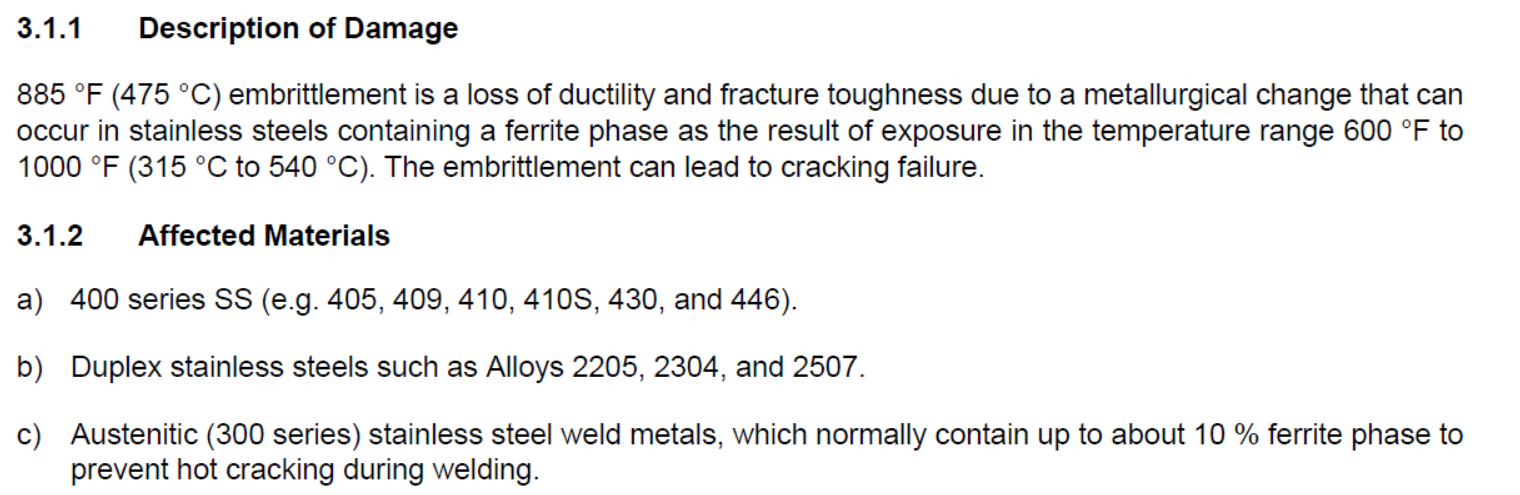

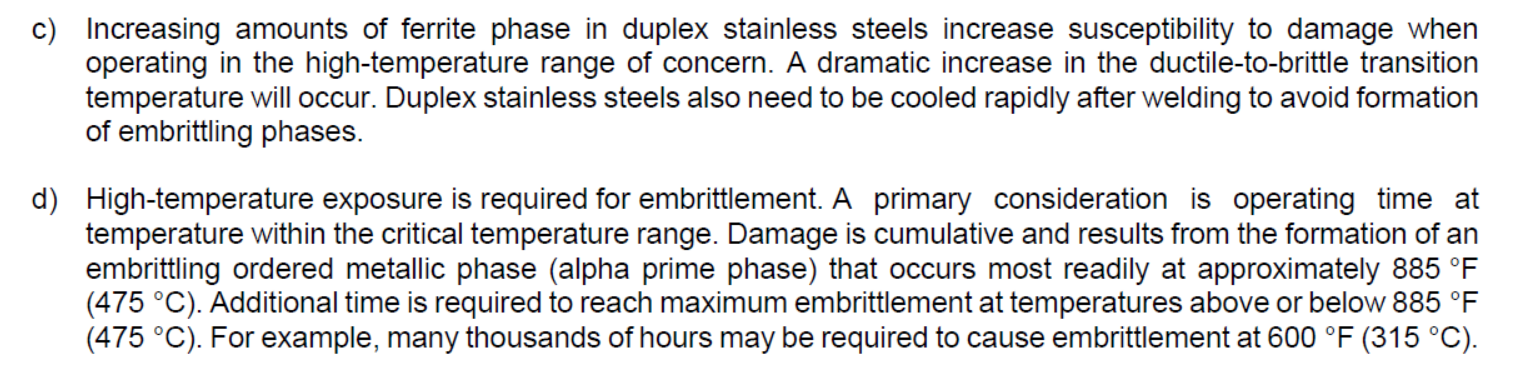

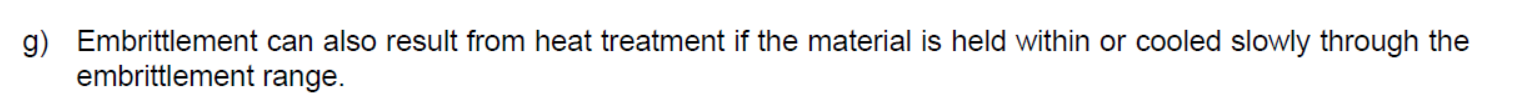

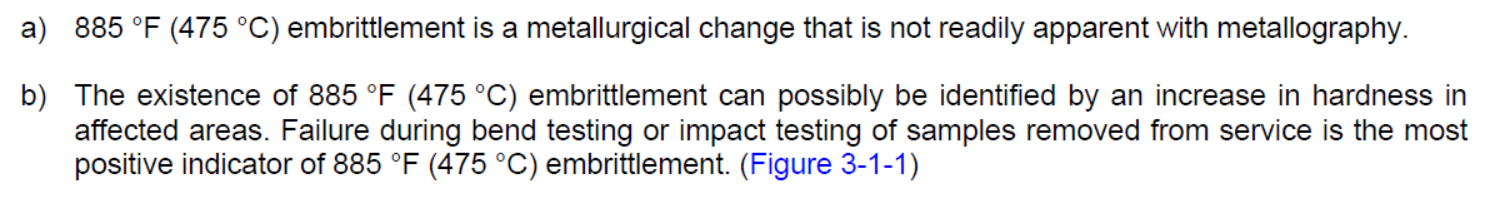

Just some info on 475degC embrittlement.Thanks & Regards

J.Gerald Jayakumar

On Tuesday, 11 October, 2022 at 07:24:35 am GMT+4, 'james gerald' via Materials & Welding <material...@googlegroups.com> wrote:sorry for being out of track.I believe the welding between Tube sheet and Shell/Channel via a LIP provided in the TS forging where you can excercise a control.Ensure DSS is not exposed to temperature greater than 400 degC to avoid 475 embrittlement (alpha prime intermetallic)Thanks & Regards

J.Gerald Jayakumar

On Monday, 10 October, 2022 at 12:55:58 pm GMT+4, Vishwas Keskar Welding Manager WELDING <vvkes...@gmail.com> wrote:Pl. note that all the HEX Tubes are also of DSS TYP S32205 .So the concerned is for these DSS tubes also.--On Monday, October 10, 2022 at 11:38:58 AM UTC+5:30 gerry_tup wrote:Thanks Prabhu.Is SCC in chloride environment a problem with SASS & 625.Moreover SASS are available mostly in European market.Thanks & Regards

J.Gerald Jayakumar

On Monday, 10 October, 2022 at 09:37:06 am GMT+4, 'Prabhu kumar Loganathan' via Materials & Welding <material...@googlegroups.com> wrote:Hello Gerald,

Yes, below specified Super ASS is an alternate to DSS due to high Cl environment, however market availability is very less which leads to long delivery time and hence suggested to go for Inconel 825 or 625, again Alloy 825 weld deposition is having cracking issues >5mm thick which is not recommended.

Regards,

L. Prabhu kumar

From: "\'james gerald\' via Materials & Welding" <material...@googlegroups.com>

Sent: Mon, 10 Oct 2022 08:55:39

To: 'Prabhu kumar Loganathan' via Materials & Welding <material...@googlegroups.com>

Subject: Re: [MW:33563] HEAT EXCHANGER CONSTRUCTION

Nice to see you back Prabhu.If service restrictions are only due to chloride concentration then we try the SASS like 904L, 254 SMO & 654 SMO/Your viewsThanks & Regards

J.Gerald Jayakumar

On Friday, 7 October, 2022 at 07:33:25 am GMT+4, 'Prabhu kumar Loganathan' via Materials & Welding <material...@googlegroups.com> wrote:Hi,

In general, DSS weld overlay is not recommended in CS due to cracking and other weldability issues. Moreover, Tube sheet forging with heavy weld overlay requires stress relieving too.

However, stress relieving is not recommended for DSS, Hence in my opinion DSS weld overlay on TS to be replaced with Alloy 625 weld overlay wherein all these these issues related to weldability & PWHT will be solved.

Regards,

Prabhu.

From: Vishwas Keskar Welding Manager WELDING <vvkes...@gmail.com>

Sent: Thu, 06 Oct 2022 09:52:15

To: Materials & Welding <material...@googlegroups.com>

Subject: [MW:33541] HEAT EXCHANGER CONSTRUCTION

Dear ExpertsOne of HEX involves following MOCs -HEX tubes - SA 789 TYP 32205Tubesheet -SA 266 CL 2 CS - Tube sheet IS cladded with TYP S32205 overlay.Shell side - CS -SA 516 GR 70 - 75mm thkChannel side - CS- SA 516 GR 70 - 75 mm thkPWHT is required for Tube sheet to Shell welding and Tube sheet to Channel welding. These are butt welds with CS Weld metal .PWHT is not required for Tube sheet to HEX Tube welding due to DSS tube to DSS cladding.Pl advice for the care that shall be taken during PWHT of Tube sheet to Shell welding and Tube sheet to Channel welding.Thanks and regardsVishwas - IWEInternational Welding Engineer--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/a163c4a4-fe95-4245...@googlegroups.com.https://groups.google.com/d/msgid/materials-welding/1665030135.S.10013.29756.f...@webmail.rediffmail.com--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit.--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1533605827.35179...@mail.yahoo.com.

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1665372339.S.23528.2356.f5-224-164.1665379709.28493%40webmail.rediffmail.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/6a3b7d65-5836-4f67-abfa-b24b6e88551an%40googlegroups.com.

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1461398998.3824451.1665405226943%40mail.yahoo.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/da57bdef-0903-4496-823b-dbed31173e06n%40googlegroups.com.

Comments