Hi Arun

Some basic explanation as per my experience.

Like in pipe 6G position weld, you will have flat , vertical and overhead welding positions,

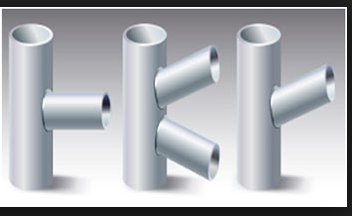

Like same way , for tubular connection joints, you will have connections like T joints, K joint & Y joints in one situation, based on you profile, angles etc...( Branch connections )

If you look from bottom you will find T shape, side way look like K shape ( when two tubular joints occurs) and from top you will find Y shape. Hence it's called TKY joint.

It is most difficult welding in off shore modules.

Since dihedral angle is less than 30deg and very difficult to pass root run welding.

Only 6GR qualified welders can weld and clear inspection requirements.

Clearing UT and Macro is very difficult unlike other joints.

Pl Refer AWS D1.1 – Section 9. Tubular Structures requirements.

Part C, Clause 9.15 & 9.16 for WPS requirements

Part D, Clause 9.19 & 9.20 for WPQ requirements

Part F, Clause 9.30 for inspection requirements.Thanks and Regards

Rameshkannan Devaraj

"What you have learned is a mere handful; What you haven't learned is the size of the world – Avvaiyar"

--Check Fig 3.7, 9.11 to 15 of AWS D1.1.Check attachment for futher information.

Regards,Mohamed Muneeb MahaboobCSWIP 3.2-89247/2ASNT-NDT-L2-RTFI-RT-UT-MT-PT.SAP#:70021650 APs:JAPID, QCS & QCI.(55:33) O company of jinn and men, if you have the power to go beyond the bounds of the heavens and the earth, go beyond them! Yet you will be unable to go beyond them for that requires infinite power.

What is the actual definition of TKY joint, please help me--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

Visit this group at https://groups.google.com/group/materials-welding.

For more options, visit https://groups.google.com/d/optout.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

Visit this group at https://groups.google.com/group/materials-welding.

For more options, visit https://groups.google.com/d/optout.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/af6cb761-e9a9-43a3-bff9-8db082f82396n%40googlegroups.com.

Comments