Use of string / Weave weld bead according to ASME Sec.IX is considered non essential variable which is considered as the requirement of ASME B31.1.

See below snap shot.

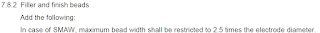

But Client Specification will have control over the Bead width. For eg see snapshot

Some consumable Manufacturer's Welding Handbook's also provides some guidance.

Normally Weaving will have an effect on the below.

1. Weld pool control depending on the Fluidity of weld liquid metal.

2. For low temperature metals will have an effect on the Charpy Impact properties as Weave width increases the Travel speed will be low and hence the Heat Input will be higher which reduces the cooling rate and hence aids in coarsening of grains and hence the charpy Impact properties.

3. Will have a problem in positional welding.

Thanks & Regards

J.Gerald Jayakumar

On Friday, 13 January, 2023 at 09:44:19 am GMT+3, G Gughan <ggughan17@gmail.com> wrote:

Weld bead width?

On Thu, 12 Jan 2023 at 12:48, Babur Khan <mbabur.bwp@gmail.com> wrote:

Greetings,Weld bead width or length?Muhammad Babur KhanSent from my iPhoneOn 12 Jan 2023, at 11:19 AM, G Gughan <ggughan17@gmail.com> wrote:--Dear Experts,--It's a very nice platform to gain & share knowledge.I have a query regarding the weld bead length. What is the maximum weld bead/weave length in Power Piping? (ASME B 31.1)orIs there any thumb rule for weld bead length?Your idea/advice will be highly welcomed & appreciated.Be safe & have a healthy LifeThanks,Kind Regards,G.Gughan

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAB0bcTMUzgWi-7pQvfdjj-e93ChHhYcq93UYgWC3xe9Kv4hnng%40mail.gmail.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/508A2E26-370D-4480-BDB4-62F5B6C0097E%40gmail.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAB0bcTMvgi%2BQhSMZTJynWBifU5CcxDDgFMQWFnCDh59xAMVG3Q%40mail.gmail.com.

Comments