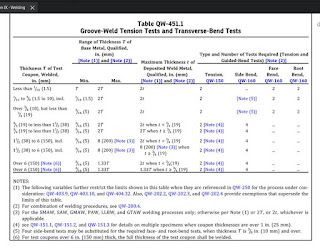

WPS thickness qualification is determined using Table QW-451.1 – see below

Your base metal thickness, 17.48mm, falls in the third grouping "Over 3/8 (10mm) but less than ¾ (19mm). Per this line, the qualified base metal thickness is 3/16 (5mm) to 2T (twice the test coupon thickness). Further, the maximum qualified weld metal thickness is 2t (twice the deposited weld metal thickness) – this is determined solely from each essential variable grouping, your case per process employed. This latter is typical.

So, for your WPS the ranges of qualification per Table QW451.1 are:

Base metal: 5mm to 34.96mm (inclusive)

GTAW weld deposit: 16mm maximum

SMAW weld deposit: 18.96mm maximum

You can, of course, limit your ranges of qualification to less than the Table QW-451.1 permitted ranges but cannot exceed them without additional qualification. So, yes, you can choose to restrict base metal thickness range to 13.1mm to 26.2mm since it is within the maximum permissible range. Likewise, you can also restrict the maximum deposit thickness to 14mm for GTAW and 18.5mm for SMAW since they are less than the maximums of 16mm and 18.96 respectively.

Note: if impact qualification is required, additional restrictions apply.

Enjoy!

From: materials-welding@googlegroups.com [mailto:materials-welding@googlegroups.com] On Behalf Of K K

Sent: Wednesday, June 26, 2019 11:37 PM

To: Materials & Welding

Subject: [MW:29753] As per Section IX Thickness range qualification

Dear Experts,

I have some difficulty to interpret the requirements of ASME section IX

I have a PQR Based on a dual process GTAW+SMAW ( 8 mm+9.48 mm) on an 17.48 mm ( 24" NPS ) butt weld.

If i am use this PQR what would be my thickness range in WPS a) Weld metal thickness range for GTAW + SMAW ? b) And what is the base metal thickness range ?

If i set in WPS base metal thickness 13.1 mm to 26.2 mm is it ok / If no than please let me know way i can't set this range.

And weld metal thickness range for GTAW - 14 mm and SMAW - 18.5 mm .

Please give with details explanation regarding my above difficulty.

Thanks and Regards

Kiran

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

Visit this group at https://groups.google.com/group/materials-welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/85413d61-938b-4d05-b22c-1c598eb6ac5d%40googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

Comments