TMCP is applied in high tensile strength thick steel plates of 490 N/mm2 or greater, and achieves marked and major improvement in characteristics such as low-temperature toughness and weldability. TMCP is used in a wide variety of fi elds such as shipbuilding,

marine structures, bridges, architecture, industrial machinery, line pipes and tanks.

1. Summary of TMCP:

TMCP is a manufacturing process of steel plates based on a combination of controlled rolling and controlled cooling. When high tensile strength steel of tensile strength ratings of 490 N/mm2 or more is manufactured by TMCP, major reduction in the amount of alloying elements added can be achieved, along with lower carbon levels. An outline of equipment used in TMCP is shown in Fig. 1.

※ TMCP (Thermo-Mechanical Control Process)

A collective name for all methods of manufacturing steel plates with controlled rolling or controlled rolling combined with accelerated cooling.

2. Characteristics of TMCP high tensile strength steel:

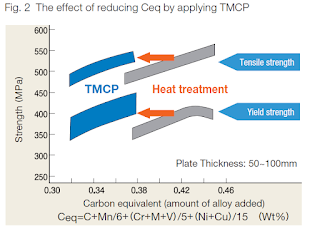

(1) Low Ceq (carbon equivalent) Toughness has been improved as a result of realization of low Ceq and utilization of TMCP.

(2) About the advantages of using TMCP high tensile strength steel plates. Weldability is greatly improved, and as a result, the following advantages are obtained during use.

• Due to the low PCM level (weld crack sensitivity composition), the preheating temperature at the time of welding can be lower than that of conventional high tensile strength steel

• The maximum hardness of the welded joints can be made lower than that of conventional high tensile strength steel

• Improving toughness of welded joints

• Less deterioration in mechanical properties of the material by linear heat

3. Examples Applications in standards

Reference for Use of Steel Plates

1.TMCP

1) The Metallographic Structure and Strength of Steel

As shown in Fig. 1, the metallographic structure and strength of steel vary greatly depending on the rate of cooling in the transformation temperature range (800 to 300°C). The transformation temperature range exists within the range over which high-temperature austenite cools to a low temperature. If the cooling is done slowly, a mixed structure of ferrite and pertly (partially bainite) with a tensile strength in the 400 to 500 MPa range, is formed. If the cooling is done more rapidly, the steel will have a bainite structure with a strength in the 600 to 800 MPa range. When cooled even more rapidly, a martensite structure with a strength of 800 MPa or more is obtained.

(2) Definition of TMCP

TMCP is a technique that, compared to conventional manufacturing processes, has a greatly expanded range of control of the metallographic structure and enables drastic reduction in grain size. TMCP is an abbreviated name of a type of steel manufacturing technique formed from the initials of Thermo-Mechanical Control Process. TMCP achieves a new structural control technique not found in conventional heat treatment methods, by combining reheating, rolling and cooling. The key technology is found in the implantation of new grain seeds (nucleus) by means of rolling, and in the reduction of grain size by means of cooling following the rolling. By combining the effect of the working in the rolling process and the effect of the control of the cooling rate in the transformation temperature range in the cooling process, a new structural control technique not found in conventional heat treatment methods was achieved.

As described above, the metallographic structure varies depending on differences in the cooling rate. Therefore, controlling the cooling rate in the temperature range in which transformation occurs is important. However, in conventional heat treatment methods, after heating the steel to a high temperature (austenite region), only two options can be used. One is to cool plates by air as cooled, and the other is to cool it as fast as possible using water (quenching). Furthermore, there were limited means for reducing the grain size and they were mainly based on controlling the heating temperature.

(3) TMCP and Grain Refinement

The basic way of thinking about reducing the grain size is that if the inside of the steel (steel plate) can be filled with a greater quantity of grains, the size of each individual grain can made small, as shown in Fig. 3. In other words, if a large number of grains are continuously formed, and furthermore if the growth of each grain is inhibited, then fine microstructures will be obtained. The key technology in TMCP is the creation of a large number of nuclei by means of rolling, and the inhibition of the growth of the grains by cooling following the rolling. The metallographic structure control technique of TMCP is not limited to the reduction of grain size. As shown in Fig. 4, the necessary characteristics can be acquired by continuously controlling the metallographic structure in each process, from the steel making process to the reheating, rolling, and controlled cooling processes of the steel plates. In addition to ferrite, TMCP can also control a wide range of high-strength metallographic structures such as martensite and bainite.

(4) Effect by Applying TMCP

The biggest effect of TMCP is that through the reduction ofgrain size and the control of metallographic structure, it is now possible to manufacture thick steel plates that have the same strength while having a drastically lower carbon equivalent (amount of alloy added). This contributes to improving efficiency in the construction of structures and to assurance of safety and reliability, through prevention of low-temperature cracking during welding, improved toughness of the welded joints and so on. TMCP is now used in most uses of thick steel plates, such as shipbuilding, architecture, bridges, line pipe, pressure vessels, and so on.

The size of grains is determined after the grain seeds (nucleus) are formed, when they grow to the point where they bump into each other.

By causing a large number of cores to form at once and inhibiting their growth, the grains can be made small.

Fig. 4 Continuous change of microstructure in TMCP ↓

Source: www.nssmc.com

Comments