On Wednesday, July 14, 2010 at 4:09:43 AM UTC-4, Bathula Raghuram (Mumbai - PIPING) wrote:

you understanding is correct, (refer note 1 of below table). hardness is the only difference

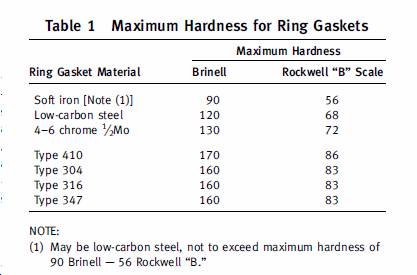

On compression of the flange assembly, it is imperative that the ring type joint be significantly softer than the flange groove so that the gasket plastically deforms and not the groove. The use of harder ring type joints can result in flange groove damage. For this reason, ring type joints are supplied with the following maximum hardness values:

From: material...@googlegroups.com [mailto:material...@googlegroups.com ] On Behalf Of Agrawal Sunil (Mumbai -Stequ)

Sent: Wednesday, July 14, 2010 12:24 PM

To: 'material...@googlegroups.com '

Subject: [MW:5978] Ring Gasket: Soft iron gasket vs. low carbon steel gasketAs per ASME B16.20, for ring gasket material, Soft iron gasket as well as Low-carbon steel gasket are mentioned, see below table from ASME B16.20

Can anyone, guide me what is the difference between SOFT IRON gasket and LOW CARBON STEEL gasket. As far as I know, SOFT IRON is having carbon content less than 0.1% and hence it is nothing but low carbon steel only.

Request opinion from group members.

Best Regards,

Sunil Agrawal

TICB

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/fa49e750-64b1-47b2-99e5-fb8ae20f451eo%40googlegroups.com.

Comments