We have recently welded 1/2" thick and 1" Thick pipes, Material : AISI 4130. Our hardness requirement is 197BHN-237BHN

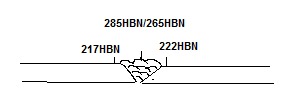

This pipes are groove welded to same size of the pipes, Followed by GTAW(ER100S-G) & SMAW(E10018-D2) process. Root is followed by GTAW and SMAW for fill up and capping.on completion of PWHT we observed following hardness value.

After completion of welding and PWHT, we have found hardness range of 285HBN and 265HBN on weld metal. Also we performed PMI on the weld metal to determine the hardness issue, during the result we found following chemical composition on the weld metal respectively.

Tabulation shows actual chemistry of the T.C

| Chemistry observed as per the T.C | ||||||||||||

|

| Size | C | Mn | Si | S | P | Cr | Ni | Mo | V | Cu |

|

| E10018-D2 | 3.2mm | 0.074 | 1.980 | 0.550 | 0.009 | 0.022 |

| 0.460 | 0.400 |

|

|

|

| 4mm | 0.068 | 1.940 | 0.510 | 0.008 | 0.021 |

| 0.690 | 0.370 |

|

|

| |

| 5mm | 0.062 | 1.980 | 0.470 | 0.009 | 0.019 |

| 0.630 | 0.340 |

|

|

| |

Tabulation shows actual chemistry after PMI inspection

| CHOKE & KILL Line | |||||||||||||

|

| Chemistry observed as per the PMI | Other metals | |||||||||||

| Weldment area | C | Mn | Si | S | P | Fe | Cr | Ni | Mo | V | Cu | Ti |

|

| On Weld Metal 90° |

| 2.00 |

|

|

| 95.33 | 0.047 | 0.807 | 0.486 | 0.03 | 0.024 | 1.2667 |

|

| On Weld Metal 180° |

| 1.966 |

|

|

| 96.616 | 0.033 | 0.838 | 0.486 | 0.00 | 0.058 | 0.00 |

|

| On Weld Metal 270° |

| 2.060 |

|

|

| 96.443 | 0.057 | 0.902 | 0.492 | 0.00 | 0.044 | 0.00 |

|

| On Weld Metal 360° |

| 2.115 |

|

|

| 96.401 | 0.363 | 0.907 | 0.501 | 0.00 | 0.037 | 0.00 |

|

| BOOSTER Line | |||||||||||||

|

| Chemistry observed as per the PMI | Other metals | |||||||||||

| Weldment area | C | Mn | Si | S | P | Fe | Cr | Ni | Mo | V | Cu | Ti |

|

| On Weld Metal 90° |

| 1.946 |

|

|

| 95.287 | 0.150 | 0.915 | 0.500 | 0.021 | 0.150 | 1.113 |

|

| On Weld Metal 180° |

| 1.992 |

|

|

| 96.362 | 0.152 | 0.932 | 0.491 | 0.00 | 0.152 | 0.00 |

|

| On Weld Metal 270° |

| 0.203 |

|

|

| 96.303 | 0.203 | 1.121 | 0.490 | 0.00 | 0.203 | 0.00 |

|

| On Weld Metal 360° |

| 0.252 |

|

|

| 96.556 | 0.252 | 0.735 | 0.480 | 0.00 | 0.252 | 0.00 |

|

On comparison of chemistry for actual observed in the T.C and PMI result varies accordingly, those variation exceeds the standard requirement of ASME Sec II part-C. Those variation are tabulated for your reference, also PMI is taken on the undiluted weld metal of the capping.

We suspect that due to exceed of Mn and Ti, hardness increased. Please suggest or advice on the following issues.

NOTE-

Interpass Temperature maintained: 300°C

Preheat Temperature maintained: 210°C

Regards

S.Sathish kumar

--

http://www.linkedin.com/groups/MaterialsWelding-122787?home=&gid=122787&trk=anet_ug_hm

The views expressed/exchnaged in this group are members personel views and meant for educational purposes only, Users must take their own decisions w.r.t. applicable code/standard/contract documents.

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To post to this group, send email to materials-welding@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/7fa8ee58-6ea4-4734-a6dc-1866048fe626%40googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

No comments:

Post a Comment