On Friday, October 19, 2018 at 4:27:35 PM UTC+5:30, ISHAAN wrote:

Dear Experts,I would like to know what is the minimum range of Plate & Piping material (thickness, Pipe size) to qualify...??? ( Min. range to pass till max allowable thick dia of material)Also I would like to Know that what are the steps to prepare PQR-WPS and what is Primary & Secondary document between them.

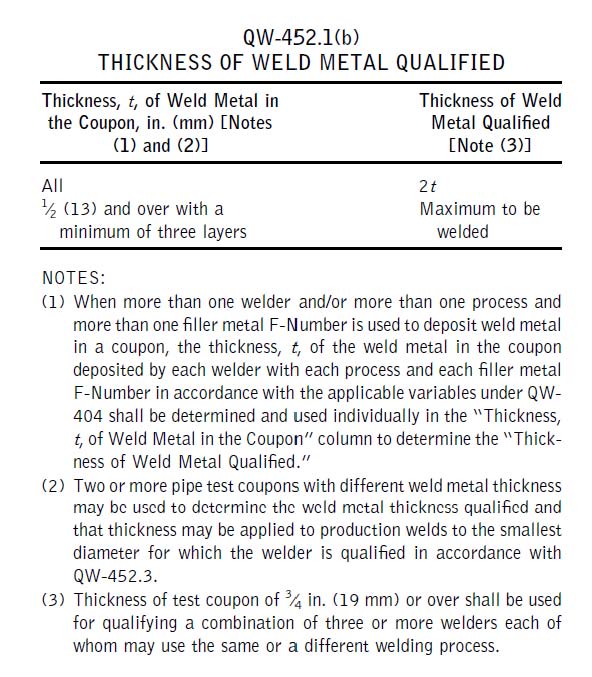

There is no minimum thickness qualified under ASME Section IX-2010 based on QW-452.1(b). The welder is qualified for a range up to 2t, where t is the thickness of the weld deposited if the weld deposited is less than 1/2 inch or less than three layer (not beads). The thickness range is unlimited if the thickness of the weld deposited is 1/2 inch or thicker and the welded sample consists of at least three layers. Your welder is qualified for unlimited thickness per QW-452.1(b) assuming at least three layers were deposited.

As for the range of pipe diameters, that depends on the diameters of the pipe. There are two categories, pipe less than or equal to 24 inches in diameter and pipe over 24 inches in diameter. In your case the pipe is over 24 inches in diameter. QW-461.9 indicates the performance qualification done on plate in the 3G position qualifies the welder for the 1G and 3G pipe positions when the pipe is over 24 inches in diameter.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

Visit this group at https://groups.google.com/group/materials-welding.

For more options, visit https://groups.google.com/d/optout.

Comments