if thick is less than 13mm, direct welding with pup piece,otherwise buttering, but pwht is issue if u weld P11+P91 directly because AC1 temp for P11 is around 745 deg celsius which is very to PWHT temp of P91

THANKS & BEST REGARDS,

KG.PANDITHAN, IWE, AWS-CWI, CSWIP 3.1,

CONSULTANT-WELDING & QUALITY

On Thu, Jun 18, 2015 at 6:03 PM, Ranendra Chakraborty <ranendrac6@gmail.com> wrote:

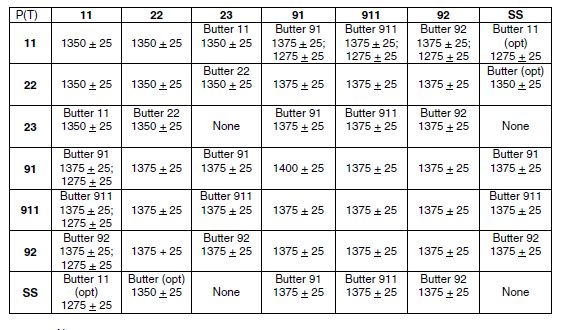

--Dear Pradip Sir,Can you share your experience which one is better buttering or direct welding for metallurgical and strengthening point of view?Regards,Ranendra ChakrabortyOn Thu, Jun 18, 2015 at 4:59 PM, pgoswami <pgoswami@quickclic.net> wrote:--Hi Arunkumar,You may follow this discussion and the provided solutions to your solve your problem. The table below provides overall electrode selection matrix for DMWs involving Grade-91 and other alloys.Thanks.Pradip Goswami, P.Eng,IWEWelding & Metallurgical Engineer/SpecialistOntario, Canada

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CANGGvaJXdNMdSigj1rX3kweoOEpD-QZis-YWQL3t5HFZr8M9PQ%40mail.gmail.com.--

From: arunkumar periasamy <arun6trix@gmail.com>

To: materials-welding@googlegroups.com

Sent: Thursday, June 18, 2015 9:36 AM

Subject: [MW:23087] Re: Whether we can weld SA 335 P11 and SA 335 P91

it is--

OD 60.3mm and Thickness= 11.07mm

pressure = 6 bars

temp= 585 c

it is an butt weld

it is not an condensing system it is an MAV system ( Lubricant supply system )

On Wednesday, June 17, 2015 at 7:29:47 PM UTC+5:30, arunkumar periasamy wrote:In my condensing system my header line is having 2 materialsThe line above sprayer which was connecting with condenser is SA 335 P11And after sprayer till loop is SA 335 P91Now my problem is whether we can weld or connect this SA 335 P11 and SA 335 P91 ?

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To post to this group, send email to materials-welding@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/f5e2364b-86a7-43d5-91c7-db540299ef3a%40googlegroups.com.To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1897297439.973280.1434611732382.JavaMail.yahoo%40mail.yahoo.com.--

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To post to this group, send email to materials-welding@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To post to this group, send email to materials-welding@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

For more options, visit https://groups.google.com/d/optout.

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To post to this group, send email to materials-welding@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/3947C1F4AA7F42D392608CD31CE283A1%40homepg.

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To post to this group, send email to materials-welding@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CANGGvaJ0JZ-T2JkfHgz84iZZUCh4bHAx8L9PP2BJoKP1hhaVJQ%40mail.gmail.com.

For more options, visit https://groups.google.com/d/optout.

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To post to this group, send email to materials-welding@googlegroups.com.

Visit this group at http://groups.google.com/group/materials-welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4eNvZwh0GLA%2BqxHE1oCPK9nK4_VWZqHL-2R%2BAqOEw-xtqw%40mail.gmail.com.

For more options, visit https://groups.google.com/d/optout.

Comments