Question is whether to do new pqr or not as per QW404.37, which is demanded by AI, But as per Code, no new PQR requirement.

THANKS & BEST REGARDS,

KG.PANDITHAN, BE, IWE, CSWIP 3.1,

ISO 9712 Level 2 in VT,

ASNT-Level II in PT,MT,RT & UT,

LA ISO 9001-2015,

International Welding Engineer.

CONSULTANT-WELDING & QUALITY

Mobile no: +919940739349

On Fri, Mar 3, 2023 at 8:14 AM 'james gerald' via Materials & Welding <materials-welding@googlegroups.com> wrote:

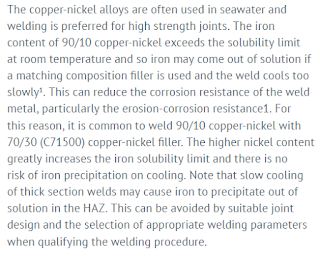

--On Wednesday, 1 March, 2023 at 04:11:50 pm IST, Jenish Mistry <jenishmistry1992@gmail.com> wrote:Dear sir ,I think dilution rate for both consumable is different because weight percentage of chemical composition is different .So that, Min. weld overlay qualification thickness for required weld overlay composition may be vary due to the dilution rate.So that,I think you should go for PQR qualification for min. Weld overlay qualification thickness for required weld Composition.--On Wed, Mar 1, 2023 at 3:29 PM Vishwas Keskar Welding Manager WELDING <vvkeskar123@gmail.com> wrote:This non ferrous weld metal.What is the F number of PQR filler metal?If PQR filler metal's F number and Production joint filler metal's F number is same ,then new PQR is not requiredThanksVishwas -IWE--On Friday, February 24, 2023 at 3:23:47 PM UTC+5:30 mohit aggarwal wrote:Dear Experts,We have equipment of weld overlay with 90/10 CuNi composition, but we have Procedure is only with 70/30 CuNi consumable.As per QW-404.37 clause our AI asked to requalify the procedure due to change of consumable.I have query can we do weld overlay of 90/10 with 70/30 consumable or we will have qualify new procedure for the same.Regards,Mohit AggarwalWelding Engineer

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/111d0d70-5570-42f9-8bfe-b914bf7c01b8n%40googlegroups.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CADXbd_evCMLdKCt4jhWsLNxcM12OSJ92KakBqoRAkRW-FbNv3w%40mail.gmail.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/337956365.1811028.1677762234919%40mail.yahoo.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4eOFkFCbgAvEvGyVHafBCb4DEwR1nHHHi8N--Je8CRiGhg%40mail.gmail.com.

Comments