Thanks in Advance,

Md. Asif Al-Istiaque Chowdhury

Construction Manager

BRS Gas Transmission Pipeline Project, Bangladesh.

Hi Asif,

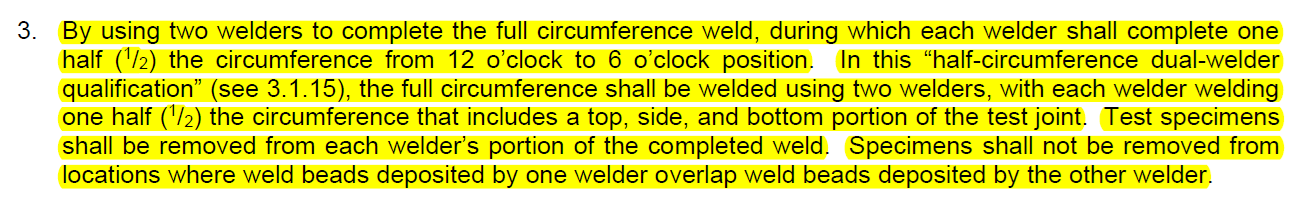

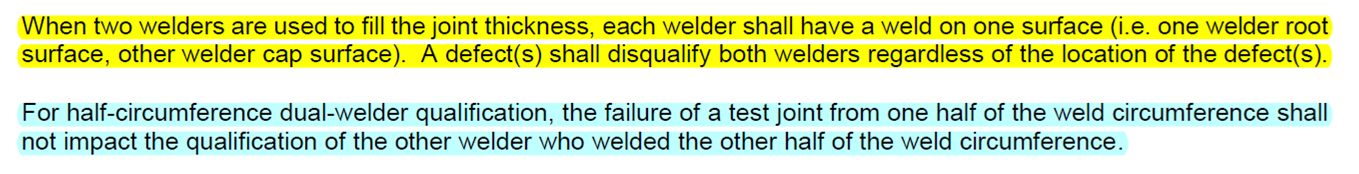

API 1104 allows this option. You should engage 2 welders max at a time.

In option 1- One welder welds the GTAW, full pass or more up to the required despot thickness , rest of the passes done by another welder by SMAW process

Option-2 Put 2 welders back-to-back, each weld half of the circumference as explained below, Both uses GTAW(root) + SMAW fill passes.

Refer Clause 6.1 of API 1104-2018, as below. However, these're the pros and cons as explained for both the welding techniques involved..

The problem one may face:-

Hopw his would help you to move forward.

Thanks.

Pradip Goswami.P.Eng, IWE.

Independent Consulting Welding & Metallurgical Engineering Specialist

Saudi Aramco Approved Designated Project Welding Engineer(DPWR)

Qatar Petroleum Approved, SME-Materials & Corrosion Engineering.

Linkedin: https://www.linkedin.com/in/pradip-goswami-2999855/

Email:pgos...@rogers.com,pradip....@gmail.com

Cell/Whasapp:1-905-9793232

From: material...@googlegroups.com <material...@googlegroups.com> On Behalf Of Engr. Asif Chowdhury

Sent: July 4, 2021 6:09 AM

To: Materials & Welding <material...@googlegroups.com>

Subject: [MW:32434] Welder Engagement in WQT

Dear Experts,

With due respect, please read following as I am in deeply need of expert's advice:

we have established a WPS with NDT and Destructive test requirements as per API 1104 which is approved by each concerned authority of my project.

Our test coupon Dia: 30 inch and Thickness: 25.4 mm

Welding Process: GTAW+SMAW

Our client consultant wants us to do WQT as One welder will do One Joint. But We have done several projects in Gas Transmission Pipeline where we have used 02 Welders for Test pieces like this during Welder Qualification Test. It seems really difficult to engage 01 welder for 01 Joint/test piece to Qualify.

Now, our Client Consultant wants reference code or standards in writing which can establish my proposal to use 02 Multi Welders for 01 Joint/test piece during Welder Qualification Test.

Also, I want to include several SMAW welders and for that I require to engage 04 welders (02 GTAW Welders+02 SMAW welders) during WQT for 01 joint/test piece.

If possible, please help me in this issue as I don't have very much knowledge about ASME 31.8, Sec IX and API 1104. I really have to establish valid point with reference code and standards in order to do the WQT by 02 welders (GTAW+SMAW) and some joints by 04 Welders (02 GTAW+02 SMAW). I request urgent help and kind cooperation with clarification for this issue from the experts in this group.

Hoping to have all of yours kind notice and help.

Thanks in Advance,

Md. Asif Al-Istiaque Chowdhury

Construction Manager

BRS Gas Transmission Pipeline Project, Bangladesh.

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/219b4deb-abdf-4218-b157-81dee64726bbn%40googlegroups.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/10f238d4-3aa1-4d3c-b3c7-785f1cbcfb66n%40googlegroups.com.

Comments